Industrial Maintenance Study Guide

This exceptionally produced trainee guide features a highly illustrated design, technical hints and tips from industry experts, review questions and a whole lot more! Key content includes Orientation to the Trade, Tools of the Trade, Fasteners and Anchors, Oxyfuel Cutting, Gaskets and Packing, Craft-Related Mathematics, Construction Drawings, Pumps and Drivers, Valves, Introduction to Test Instruments, Material Handling and Hand Rigging, Mobile and Support Equipment and Lubrication. Instructor Supplements Instructors: Product supplements may be ordered directly through OASIS.

For more information contact your Pearson NCCER/Contren Sales Specialist. Annotated Instructor's Guide Paperback 0-13-228609-2. Computerized Testing Software 0-13-229107-X.

Maintenance Positions Study Guide. 2) Aids in the activation of a number of biochemical processes within the plant e) Manganese (Mn). 1) Important to the. This Study Guide is for Industrial Electricity 1, a base-level exam that focuses within the. It is appropriate as an entry level exam for both industrial maintenance. The Industrial Skills Test (IST) is designed to measure an applicant's skill and aptitude toward. Warehouse staff; Construction workers; Count and stack workers; Maintenance etc. Two full-length Bennett–style practice tests & study guides.

Study Guide Template

Transparency Masters 0-13-229160-6. PowerPoint® Presentation Slides (to be used for both Industrial Maintenance Electrical & Instrumentation Level 1 and Industrial Maintenance Mechanic Level 1) 0-13-608643-8.

Table of Contents (Total Level Hours: 195; includes 72.5 of Core Curriculum) 32101-07 Orientation to the Trade (2.5 Hours) Covers the history of the trade, and the kinds of work and work environments industrial maintenance craftspeople would find in the field. Describes the apprenticeship and training programs available, as well as the career opportunities in industrial maintenance. The responsibilities and characteristics a worker should possess are also described. 32102-07 Tools of the Trade (5 Hours) Provides an introduction to the hand and power tools used in industrial maintenance.

Covers safety procedures and techniques for use of these tools. 32103-07 Fasteners and Anchors (5 Hours) Covers the hardware and systems used by an industrial maintenance craftsperson. Describes various types of anchors and supports, their applications, and how to install them safely. 32104-07 Oxyfuel Cutting (17.5 Hours) Explains the safety requirements for oxyfuel cutting. Identifies oxyfuel cutting equipment and provides instructions for setting up, lighting, and using the equipment. 1992 jeep cherokee xj shop manual download.

Includes straight line cutting, piercing, beveling, washing, and gouging. 32105-07 Gaskets and Packing (10 Hours) Introduces types of gaskets and gasket material, types of packing and packing material, and types of O-ring material. Explains the use of gaskets, packing, and O-rings, and teaches how to fabricate a gasket. 32106-07 Craft-Related Mathematics (15 Hours) Explains how to use ratios and proportions, solve basic algebra, area, volume, and circumference problems, and solve for right triangles using the Pythagorean theorem. 32107-07 Construction Drawings (12.5 Hours) Introduces plot plans, structural drawings, elevation drawings, as-built drawings, equipment arrangement drawings, P&IDs, isometric drawings, basic circuit diagrams, and detail sheets. 32108-07 Pumps and Drivers (5 Hours) Explains centrifugal, rotary, reciprocating, metering, and vacuum pump operation and installation methods, as well as types of drivers. Also covers net positive suction head and cavitation.

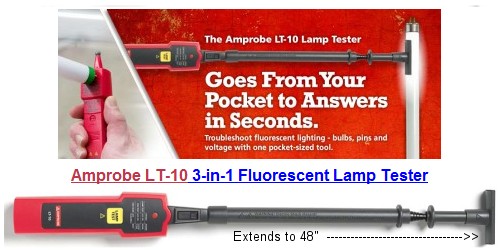

32109-07 Valves (5 Hours) Identifies and provides installation methods for different types of valves. Also covers valve storage and handling. 32110-07 Introduction to Test Instruments (7.5 Hours) Introduces the basic test equipment for industrial maintenance, including tachometers, pyrometers, strobe meters, voltage testers, and automated diagnostic tools.

32111-07 Material Handling and Hand Rigging (15 Hours) Introduces the equipment and techniques of material handling, and describes the procedures for rigging and communicating with riggers. 32112-07 Mobile and Support Equipment (10 Hours) Introduces the safety procedures and methods of operation for motorized support equipment, including forklifts, manlifts, compressors, and generators. 32113-07 Lubrication (12.5 Hours) Explains lubrication safety, storage, and classifications. Also explains selecting lubricants, additives, lubrication equipment, and lubricating charts. Package ISBN-13: $549.33 This package contains:.

Industrial Maintenance Mechanic Level 1 Trainee Guide, Paperback, 3rd Edition By ©2006 Paper; 536 pages. Industrial Maintenance Mechanic Level 3 Trainee Guide, Paperback, 3rd Edition By ©2008 Paper. Core Curriculum Trainee Guide, 5th Edition By ©2016 Paper; 592 pages. Industrial Maintenance Mechanic Level 4 Trainee Guide, Paperback, 3rd Edition By ©2009 Paper. Industrial Maintenance Mechanic Level 2 Trainee Guide, Paperback, 3rd Edition By ©2008 Paper.

Comments are closed.